Our locations

Castelnuovo – Modena

Prosciutto M.E.C, Prosciutto di Modena D.O.P, Prosciutto Nazionale

120 DIPENDENTI

36.390 mq SUPERFICIE TERRENO

22.460 mq SUPERFICIE EDIFICATA

- Cured Prosciutto crudo

P.D.O Prosciutto of Modena

National Prosciutto

120 EMPLOYEES

36.390 mq LAND AREA

22.460 mq BUILT-UP AREA

Medesano – Parma

Prosciutto di Parma D.O.P.

15 EMPLOYEES

26.990 mq LAND AREA

6.970 mq BUILT-UP AREA

P.D.O Prosciutto of Parma

15 EMPLOYEES

26.990 mq LAND AREA

6.970 mq BUILT-UP AREA

Headquarters

Castelnuovo Rangone since 1979

Cured Prosciutto crudo, Prosciutto di Modena D.O.P, Prosciutto Nazionale

120 EMPLOYEES

36.390 mq LAND AREA

22.460 mq BUILT-UP AREA

M.E.C Prosciutto

P.D.O Prosciutto of Modena

National Prosciutto

120 EMPLOYEES

36.390 mq LAND AREA

22.460 mq BUILT-UP AREA

Headquarters

Monastery of Medesano since 1997

Prosciutto di Parma D.O.P.

15 EMPLOYEES

26.990 mq LAND AREA

6.970 mq BUILT-UP AREA

P.D.O Prosciutto of Parma

15 EMPLOYEES

26.990 mq LAND AREA

6.970 mq BUILT-UP AREA

The production process

Trimming

The first pork leg processing operation involves trimming the fresh leg. With this step we try to give the product the classic round shape, removing the parts of fat and excess rind.

Salting

The product is then divided according to the weight and brought to the salting line where the thigh is covered with salt to allow it to begin to release the water contained in the tissues. The ham is then left to rest in refrigerated cells. This operation is repeated a second time after a few days to finish with the vertical arrangement of the product until the end of the cold phase rest, with the change of state from fresh meat to seasoned product.

Salting

The product is then divided according to the weight and brought to the salting line where the thigh is covered with salt to allow it to begin to release the water contained in the tissues. The ham is then left to rest in refrigerated cells. This operation is repeated a second time after a few days to finish with the vertical arrangement of the product until the end of the cold phase rest, with the change of state from fresh meat to seasoned product.

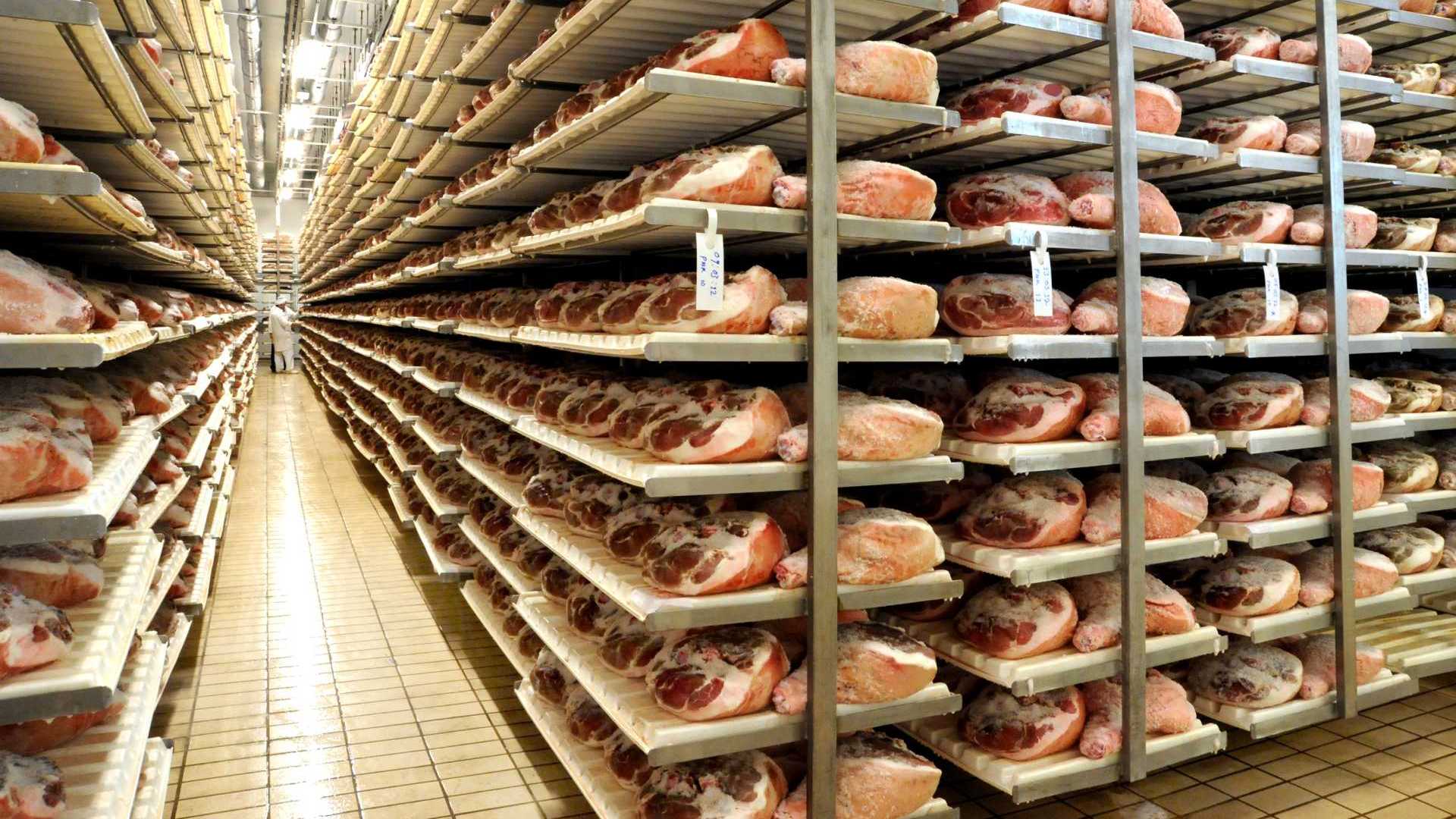

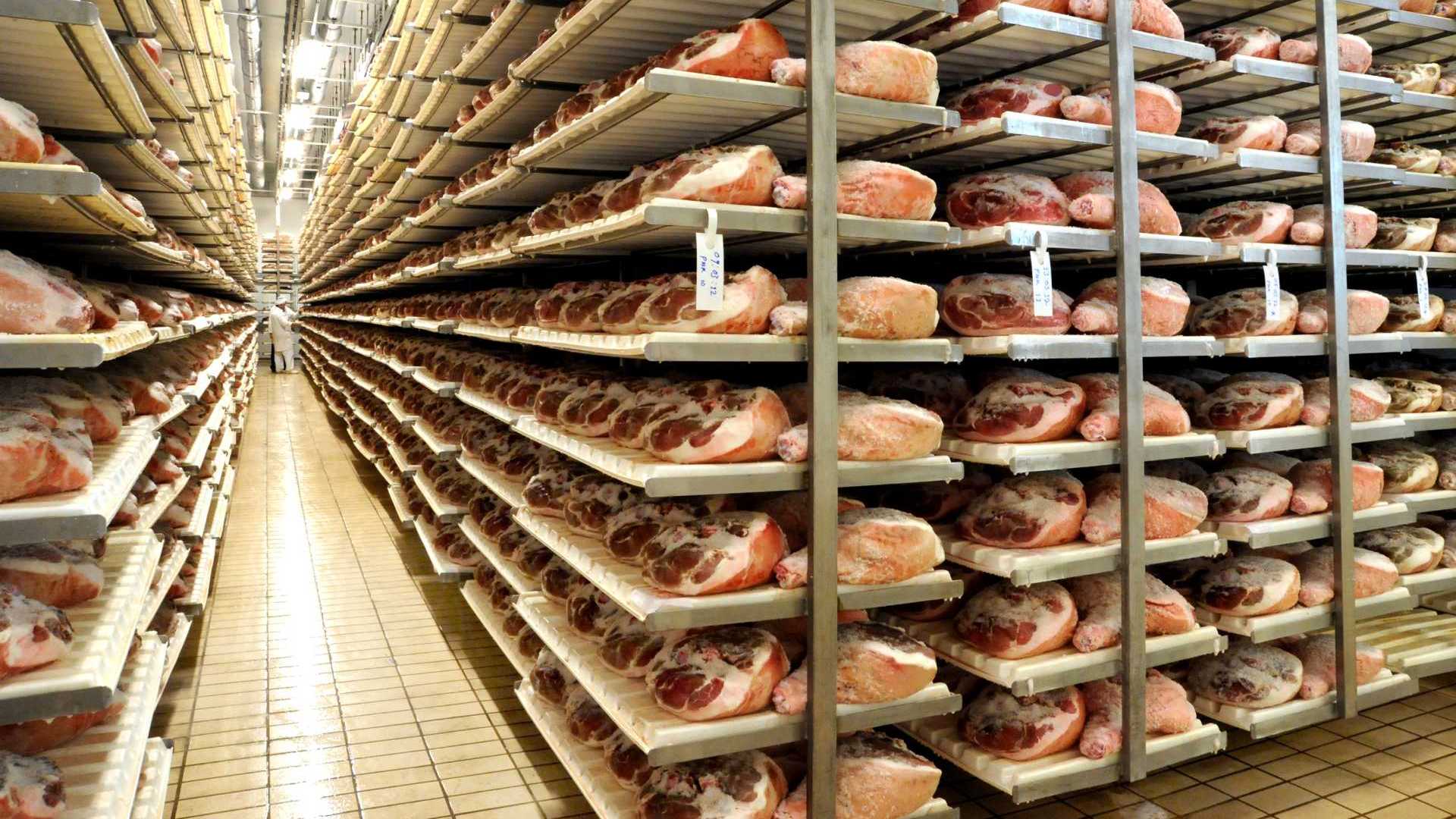

Seasoning

At the end of the rest, the pre-staging phase begins in “hot” rooms at the end of which the part of the ham not protected by the rind is spread with lard. The ham is then placed in the seasoning rooms where temperature and humidity are controlled by leading systems to finish its production process.

Quality Check

During the seasoning process, the ham begins to be probed, through the use of a horse bone needle that expert experts make penetrate into precise points of the ham, in order to highlight any defects that can be identified through olfactory problems.

Quality Check

During the seasoning process, the ham begins to be probed, through the use of a horse bone needle that expert experts make penetrate into precise points of the ham, in order to highlight any defects that can be identified through olfactory problems.

Boning

Products that, for customer’s needs, are not sold in bone, are selected according to size, type and seasoning and are transferred to the rooms used for boning. Once the femoral bone is removed, the ham is processed to obtain the various types of product: open, slipped, decorated, pressed, tile and portioned.

Packaging

The final operation consists in vacuum packaging the product in order to create an anaerobic environment that minimizes the danger of bacterial proliferation during the Shelf Life period. Packaging materials meet all the requirements laid down in the Community regulations currently in force in respect of MOCA, establishing their alimentary properties.

Packaging

The final operation consists in vacuum packaging the product in order to create an anaerobic environment that minimizes the danger of bacterial proliferation during the Shelf Life period. Packaging materials meet all the requirements laid down in the Community regulations currently in force in respect of MOCA, establishing their alimentary properties.